HAND LAID IN CANADA

At We Are One, we control every aspect of production in-house. From design and engineering to machining and hand-laying carbon, our vertically integrated process allows us to push the limits of performance and precision. Our proprietary carbon layups are designed to withstand the harshest riding conditions.

Based in British Columbia, home to some of the world’s most challenging terrain and riders, we know what it takes to build rims that thrive in extreme conditions. For us, durability and precision aren’t just features—they’re essential.

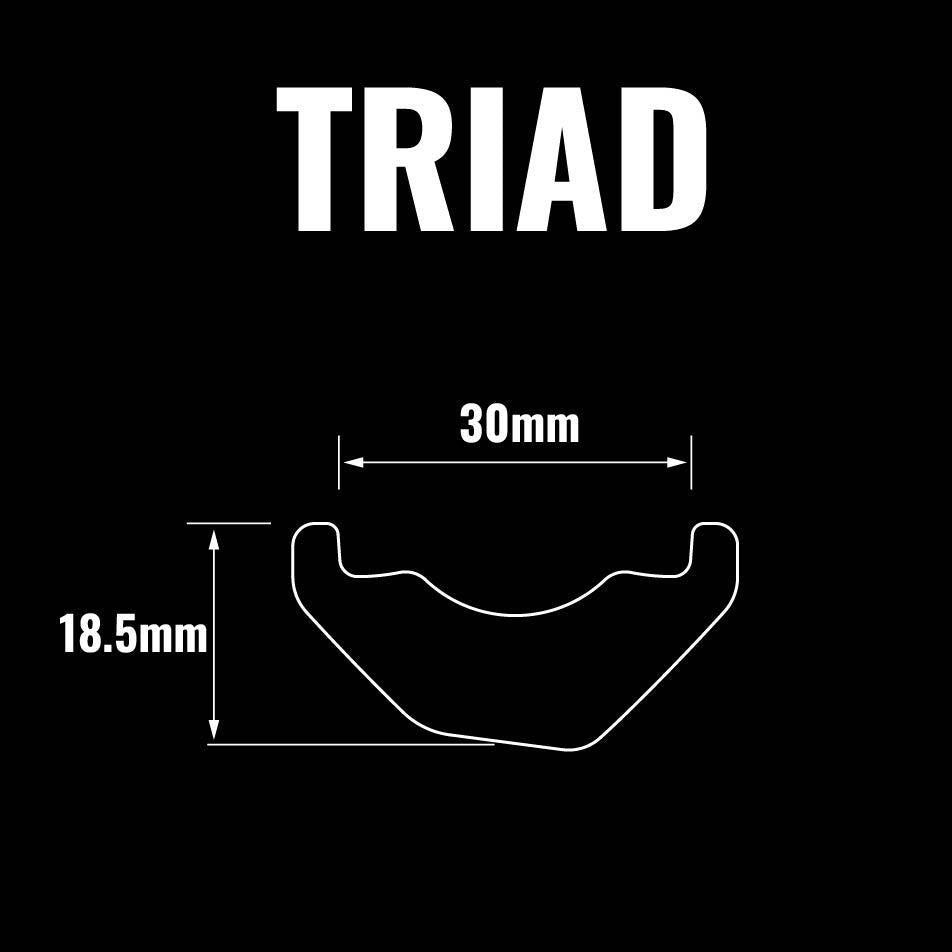

CONVERGENCE RIMS

The Convergence series represents the pinnacle of our engineering, delivering a ride feel that’s unmatched. Featuring our exclusive sinuous profile, Convergence rims are designed to optimize spoke bracing angles for a stronger, more responsive, and consistent wheel.

This unique profile isn't just for aesthetics—it's stronger by design. The shape aligns the inner wall of the rim with the spoke bracing angle, ensuring the nipple sits flatter, reducing stress on both nipples and spokes. With 7.5° alternating faces, the rim ensures a perfect perpendicular angle, minimizing fatigue and prolonging service intervals.

The result is an engineered wheelset built to maximize durability while delivering more speed, less maintenance and a more consistent ride.

Ride Canada’s Best

Unleashing innovation and performance, all built by Canadian hands for riders who demand more.

Engagement

G3 hubs use the same 72 tooth drive ring and three-step magnetically actuated pawls as our proven G2 hubs. Project321 wanted to increase engagement without compromising reliability. To do so, they added two additional pawls to increase engagement, instead of miniaturizing the teeth on the drive ring and pawls. A total of eight pawls work in teams of two, to give 1.25° or 288 points of engagement. Project321 believes this gives riders the ideal balance of instant engagement and rock-solid reliability.

6-Lock

6-Lock is a new patent pending technology by Project321. 6-Lock is an enhanced six bolt design that features stainless steel bolt threads. No lockring is required, only T25 Torx hardware, giving the rider true six bolt rotor retention. 6-Lock easily converts to center lock, giving you unrestrained brake rotor optionality.

6-lock utilizes a stainless steel collet that locks into the channel behind the splines on a center lock brake mount. Stainless steel threads eliminate the risk of stripping and significantly improve bolt retention. A 7075 aluminum flange fits over the collet to support it while locking onto the center lock splines, providing a strong brake mount interface for any six bolt rotor. The system also adds redundancy as it is completely modular.

Axle & Bearing Layout

Project321 has updated their hub’s internal architecture as well, and G3 hubs showcase an entirely new axle and bearing layout. The new design features two double-row bearings to provide additional support at the highest stress point of the axle, with the intention of making broken axles a thing of the past. G3 axles are fully anodized 7075 aluminum, and Project321 have maintained preload adjustment on its rear hubs to allow you to achieve perfect bearing preload. The company is so confident in their axle design (also utilized in Stan’s M-Pulse hubs since the beginning of 2022), they are giving customers a 10-year warranty on them.

Sealing System

G3 hubs have Project321’s most robust sealing system yet, which was codeveloped with Stan’s during the development of Stan’s M-Pulse hubs. The system is comprised of a low-drag light-contact rubber seal that is pressed into the hubshell, and an aluminum dust shield pressed onto the driver body. This improved two-piece system keeps oil in, and contaminants out.